H1 2023: In H1 2023, prices of Thermoplastic Elastomer (TPE) fluctuated in the Asia Pacific region. In the first three months of 2023, there was an upward trend in TPE prices in the Asia-Pacific region. TPE was stocked up in the Chinese market in January as a result of a decrease in consumption from downstream sectors. In February, prices rose in Chin as more orders from Chinese markets were received, and the retailers refilled the inventory. Thermoplastic Elastomer (TPE) prices in the Asian market showed a slight increase in April 2023. The situation was optimistic at first but stabilized by the end of June 2023. Despite the region's sluggish economic growth, the rebound in demand from Southeast Asia's downstream automotive sector was primarily responsible for this increase in thermoplastic elastomer (TPE) pricing. Because of low feedstock styrene costs, production was mild, but supply was constrained because of fewer production units operating because of the Labor Day holidays. Despite the fact that demand from the automotive industry initially increased, it eventually lowered at the conclusion of the second quarter of 2023.

The global Thermoplastic Elastomer (TPE) market stood at approximately 4900 thousand tonnes in 2022 and is anticipated to grow at a CAGR of 3.5% during the forecast period until 2032. Development activities are stimulating demand for Thermoplastic Elastomer (TPE) due to rising disposable incomes, rising living standards, and increasing urbanization. Moreover, one of the main factors influencing the growth of the industry as a whole is the growing need for electronics in emerging economies.

Thermoplastic Elastomer (TPE) is a special kind of synthetic rubber that combines the benefits of plastic production and recyclability with the properties of rubber. TPEs may be stretched to at least twice their original length at room temperature and typically have a low modulus. TPEs only experience physical cross-linking, which is reversible with heat, as opposed to the chemical cross-linking found in thermoset rubbers. TPEs are a reusable option because of this feature. TPEs are processible because they don't always need stabilizers or reinforcing agents during manufacture. Thermoplastic elastomers, like plastics, are primarily fabricated by melting processes, the amount of which is dictated by the material's flow during elevated temperatures. TPEs have applications in the automotive, construction, electronics, and other industries. Weather seals for automobiles, shock dust boots, bumpers, exterior and interior components, trims, air ducts, pipe grommets, glass encapsulation, drive belts, high- and low-pressure pipes, motor scooter mats, and O-rings are some its applications in Automotives. In construction sector, TPEs are used to manufacture pipe seals, glazing seals, simple or co-moulded hydraulic seals, and extruded seals for doors and windows. In consumer items, TPEs is used to make refrigerator magnetic seals, power tool handles, smartphone covers, push-button panels, remote control covers, and vacuum cleaner shock-absorbing guards. In the medical sector, applications of TPE include breathing tubes, ventilation masks, bags, valves, syringe seals tips, and catheters. In electronics, TPEs is used to make Technology Condenser sheaths, plugs and loose sockets, specialist cables, and parts for mobile phones.

Innovations in the automobile sector are a result of consumers' growing need for lightweight vehicles. Thus, it is propelling the expansion of the thermoplastic elastomer market. These materials are utilized in a variety of automobile applications, including automotive gaskets, door and window handles, exterior filler panels, and wipers. The market would expand rapidly if different kinds of thermoformed elastomers were used to produce lightweight automobiles. Also, the demand for consumer goods including wires and cables, tubes, and small kitchen appliances is rising, is likely to lead to a global growth in the use of thermoplastic elastomers. Furthermore, it is anticipated that the increase in population would spur more building activity, which will most probably accelerate market expansion. Investments in medical equipment, including plastic syringes, instruments, surgical gloves, and other plastic goods used in consumer and industrial applications, are anticipated to increase in response to rising healthcare and medical facilities, which is likely to spur the TPE market expansion. Owing to these reasons, the global Thermoplastic Elastomer (TPE) market is likely to reach approximately 6900 thousand tonnes in 2032.

In terms of geography, the TPE is largely consumed by the Asia Pacific region. Due to the strong need for plastics in the automotive, electrical and electronics, packaging, and construction industries, the region is one of the biggest users of TPE. The main growth markets in Asia Pacific are anticipated to be China, India, and Southeast Asia. Because of its varied uses, ease of moulding, and ability to take on the desired shape, TPE and other polymers are widely used in all industries. Furthermore, it is anticipated that the growing middle class in the area will raise demand for vehicles. Furthermore, the thermoplastic elastomers (TPE) market in China had the most market share, while the market in India had the quickest rate of growth in the Asia-Pacific region.

The global market for methacrylic acid is divided into these segments on the basis of type: SBC (Styrene Butadiene Copolymer), TPO (Including TPV), TPU, and Others (COPE, COPA, etc). Due to rising consumer demand from a variety of industries, including automotive, construction, medical, footwear, electrical & electronics, and others, the styrenic block copolymers segment led the market in 2022 Furthermore, the trend toward lighter cars is one element that is expected to bolster this market's expansion.

Based on the end-user industry, the global Thermoplastic Elastomer (TPE) market is divided into Automotive, Construction Industry, Plastic Engineering, Wire & Cable, and Others. However, Automotive is dominating the global Thermoplastic Elastomer (TPE) market and held about 52% of the global Thermoplastic Elastomer (TPE) market in 2022 and is anticipated likely to maintain its position in the upcoming years. Car parts such as wipers, external panels, bonnets, are made of thermoplastic elastomers (TPE).

Major players in the Global Thermoplastic Elastomer (TPE) market are Arkema S.A., BASF SE, Bayer MaterialScience LLC, China Petroleum & Chemical Corporation, Dynasol Elastomers LLC, EMS Group, Evonik Industries, Huntsman Corporation, Kraton Polymers LLC, LG Chemicals, LCY Chemical Corporation, Lubrizol Corporation, LyondellBasell Industries, Nippon Polyurethane Industry Company Ltd., The Dow Chemical Company, and TSRC Corporation.

Years considered for this report:

Historical Period: 2015- 2022

Base Year: 2022

Estimated Year: 2023

Forecast Period: 2024-2032

This report will be delivered on an online digital platform with one-year subscription and quarterly update.

Objective of the Study:

• To assess the demand-supply scenario of Thermoplastic Elastomer (TPE) which covers production, demand and supply of Thermoplastic Elastomer (TPE) market in the globe.

• To analyse and forecast the market size of Thermoplastic Elastomer (TPE)

• To classify and forecast Global Thermoplastic Elastomer (TPE) market based on end-use and regional distribution.

• To examine competitive developments such as expansions, mergers & acquisitions, etc., of Thermoplastic Elastomer (TPE) market in the globe.

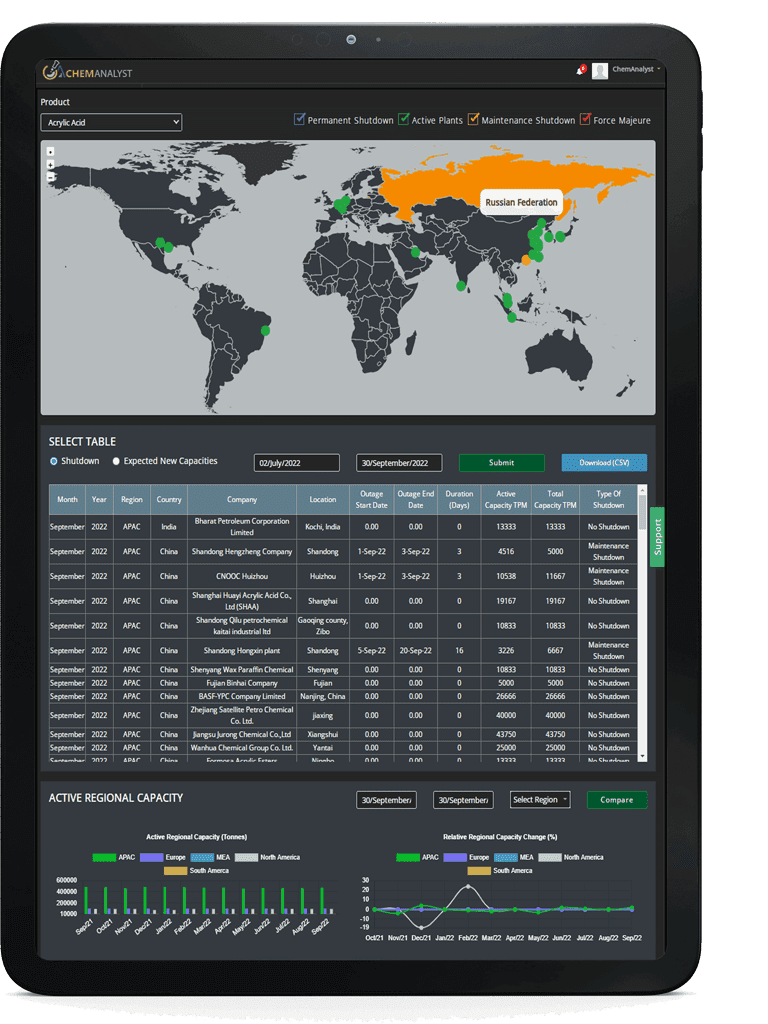

To extract data for Global Thermoplastic Elastomer (TPE) market, primary research surveys were conducted with Thermoplastic Elastomer (TPE) manufacturers, suppliers, distributors, wholesalers and Traders. While interviewing, the respondents were also inquired about their competitors. Through this technique, ChemAnalyst was able to include manufacturers that could not be identified due to the limitations of secondary research. Moreover, ChemAnalyst analyzed various segments and projected a positive outlook for Global Thermoplastic Elastomer (TPE) market over the coming years.

ChemAnalyst calculated Thermoplastic Elastomer (TPE) demand in the globe by analyzing the historical data and demand forecast which was carried out considering the production of raw material to produce Thermoplastic Elastomer (TPE). ChemAnalyst sourced these values from industry experts and company representatives and externally validated through analyzing historical sales data of respective manufacturers to arrive at the overall market size. Various secondary sources such as company websites, association reports, annual reports, etc., were also studied by ChemAnalyst.

Key Target Audience:

• Thermoplastic Elastomer (TPE) manufacturers and other stakeholders

• Organizations, forums and alliances related to Thermoplastic Elastomer (TPE) distribution

• Government bodies such as regulating authorities and policy makers

• Market research organizations and consulting companies

The study is useful in providing answers to several critical questions that are important for industry stakeholders such as Thermoplastic Elastomer (TPE) manufacturers, customers and policy makers. The study would also help them to target the growing segments over the coming years (next two to five years), thereby aiding the stakeholders in taking investment decisions and facilitating their expansion.

Report Scope:

In this report, Global Thermoplastic Elastomer (TPE) market has been segmented into following categories, in addition to the industry trends which have also been detailed below:

|

Attribute

|

Details

|

|

Market size Volume in 2022

|

5900 thousand tonnes

|

|

Market size Volume in 2032

|

9100 thousand tonnes

|

|

Growth Rate

|

CAGR of 4.5% from 2023 to 2032

|

|

Base year for estimation

|

2023

|

|

Historic Data

|

2015 – 2022

|

|

Forecast period

|

2024 – 2032

|

|

Quantitative units

|

Demand in thousand tonnes and CAGR from 2023 to 2032

|

|

Report coverage

|

Industry Market Size, Capacity by Company, Capacity by Location, Operating Efficiency, Production by Company, Demand by Type, Demand by End- Use, Demand by Region, Demand by Sales Channel, Demand-Supply Gap, Company Share, Manufacturing Process.

|

|

Segments covered

|

By End-Use: (Automotive, Construction Industry, Plastic Engineering, Wire & Cable, and Others)

By Sales Channel: (Direct Sale and Indirect Sale)

|

|

Regional scope

|

North America, Europe, Asia Pacific, Middle East and Africa, and South America.

|

|

Pricing and purchase options

|

|

Available Customizations:

With the given market data, ChemAnalyst offers customizations according to a company’s specific needs.

In case you do not find what, you are looking for, please get in touch with our custom research team at sales@chemanalyst.com