Welcome To ChemAnalyst

The development of fluorescent and photoluminescent materials is a complex interplay of nanotechnology applications and material science. In a recent study conducted by a team of researchers from various Saudi Arabian institutions, they have explored the use of electrospun glass nanofibers (GNFs) to enhance polycarbonate (PC) for the creation of such materials. The key to this development lies in the integration of lanthanide-activated aluminate (LA) nanoparticles (NPs) into transparent GNFs@PC smart sheets.

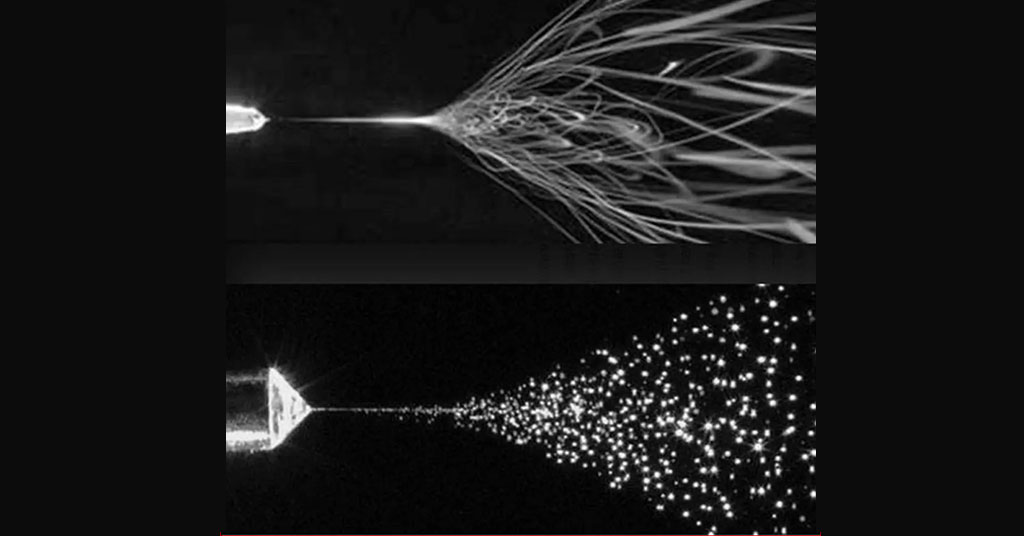

The research team conducted spectral investigations, utilizing photoluminescence and CIE Lab parameters, to showcase the transformative potential of these materials. When exposed to UV light, the previously translucent GNFs@PC smart sheets undergo a rapid metamorphosis, changing their appearance to a vivid green, thereby exhibiting fluorescence activity. This transformation is swift and reversible when the LANPs concentration is low, indicating fluorescence emission. However, higher concentrations of phosphors in GNFs@PC result in longer-lasting afterglow photoluminescence and slower reversibility, expanding the versatility of these materials.

TEM was employed by the scientists to examine the GNFs and LANPs, uncovering particle dimensions ranging between 11 and 26 nm and fiber widths measuring 250 to 300 nm, correspondingly. The GNFs were produced using electrospinning technology and were subsequently incorporated into PC sheets. This integration significantly enhanced scratch resistance compared to LANPs-free PC samples. Notably, increasing the LANP concentration also improved hydrophobicity and UV protection.

To create UV-responsive smart materials, LANPs were loaded into the GNFs@PC hybrid host material. Electrospinning played a crucial role in crafting the GNFs, reinforcing the PC bulk. The resulting fluorescent and afterglow emission characteristics of the GNFs@PC substrates make them suitable for various applications, including smart windows and smart concrete. This approach enabled the development of hybrid nanocomposites comprising LANPs, GNFs, and PC, which demonstrate luminescence when exposed to UV light and maintain transparency in visible light conditions.

Through this straightforward procedure, the researchers achieved a transparent appearance, UV protection, photostability, and hydrophobicity in the photoluminescent GNFs@PC substrates. Morphological features were further analyzed using techniques such as energy-dispersive X-ray spectroscopy (EDXA), X-ray fluorescence (XRF), and scanning electron microscopy (SEM), confirming the exceptional quality of the resulting materials.

The study also explored the contact angle of the light-emitting GNFs@PC hybrid nanocomposites. As the LANPs ratio increased from 0.5% to 8%, the contact angle of these nanocomposites increased from 148.6° to 158.7°. The optimal LANPs ratio at 1% resulted in colorless GNFs@PC with maximum green emission under UV light. Furthermore, a LANPs-to-GNFs@PC ratio of 6% produced the brightest green phosphorescent emission, providing a vivid greenish-yellow glow even in the dark.

In essence, this research represents a significant advancement in the development of luminescent materials. By utilizing electrospun glass nanofibers to enhance polycarbonate and incorporating lanthanide-activated aluminate nanoparticles, the researchers have created materials with versatile luminescent properties. These materials have the potential for various applications, including smart windows and smart concrete, offering a unique blend of fluorescence and afterglow emission. The study's findings also underscore the importance of precise control over nanoparticle concentrations in achieving specific luminescent properties, as demonstrated by the contact angle and emission characteristics observed at different LANPs ratios.

We use cookies to deliver the best possible experience on our website. To learn more, visit our Privacy Policy. By continuing to use this site or by closing this box, you consent to our use of cookies. More info.