H1 2023: In H1 2023, the Asia Pacific region emerged as the largest consumer of Neopentyl Glycol (NPG). In H12023, in the Asia-Pacific market, Neopentyl Glycol (NPG) experienced a mixed market. Post the Lunar holidays in February, prices experienced an upward trajectory fuelled by greater inquiries and increased prices of feedstock Isobutyraldehyde in the Chinese market. In the Chinese market, NPG prices began to slip from March 2023. Conversely, in India, NPG prices surged sharply in January due to limited availability. In February, despite ample inventory from other Asian countries and minimal imports for the Indian market, traders managed to meet downstream industry demands. Notably, in March 2023, freight and shipping costs witnessed a substantial decline in India. April 2023 onwards, pessimistic market sentiments characterized the Asian Neopentyl Glycol. Key factors contributing to the downturn included decreasing raw material prices and diminished demand from end-users. The construction and automotive sectors, significant consumers of Neopentyl Glycol, faced sluggish demand in Asia. The construction industry, in particular, witnessed a downturn in Q2 2023 in the Asian nations. Additionally, in the face of growing inflationary pressure and an economic slowdown and dampened bulk consumer enthusiasm. Despite regional inflation, demand from the automotive sector remained steady. The absence of procurement orders, especially from South Korea, and surplus material availability further influenced the prevailing price trend, supporting the contraction of demand-supply fundamentals.

The global Neopentyl Glycol (NPG) market stood at approximately 750 thousand tonnes in 2022 and is likely to further grow at a CAGR of 3.7% during the forecast period until 2032. Neopentyl Glycol (NPG) is a white crystalline powder, soluble in various compounds including water, benzene, and ethanol. With a melting point of approximately 129°C, it exists as a solid at room temperature. Commercially, NPG is produced through the Aldol reaction, where Formaldehyde and Isobutyraldehyde combine to form a product known as Aldol, subsequently yielding Neopentyl Glycol.

Neopentyl Glycol (NPG) is a pivotal chemical compound with diverse applications in the chemical industry, notably contributing to the synthesis of various high-performance materials. In the production of polyester resins, NPG serves as a fundamental building block, facilitating the formulation of coatings, adhesives, and unsaturated polyester resins. Widely utilized in coatings manufacturing, particularly in automotive and industrial sectors, NPG enhances durability and weathering resistance. Furthermore, its role in polyurethane synthesis extends to the production of flexible and rigid foams, coatings, and elastomers. NPG's application as a plasticizer enhances the flexibility and performance of polymers, while its inclusion in alkyd resin formulations is integral to the production of paints, varnishes, and coatings. In the adhesive sector, NPG contributes to improved bonding properties in various industrial applications. Additionally, NPG finds application in lubricant formulations, where it influences viscosity and overall performance characteristics. Neopentyl glycol is employed in the formulation of polyester polyols utilized in polyurethane coatings designed for applications in automotive, industrial maintenance, transportation, and aerospace sectors. Neopentyl glycol (NPG) primarily functions as a foundational component for coating resins. These include saturated polyesters widely utilized in powder coatings, unsaturated polyesters, and alkyd resins employed in metal coatings. Additionally, NPG is utilized in the creation of polyurethane resins, which are employed as adhesives in automotives. NPG is also used as plasticizers and lubricants for polyester. NPG finds extensive applications in the automotive, construction, furniture, electronics, and pharmaceutical industries. Other note-worthy applications of NPG are also in hydraulic fluids, synthetic lubricating oils, greases, metalworking fluids, and lubricants for aircraft engines.

Neoprene glycol (NPG) demand is anticipated to be driven by the growing need for coating resins from end-use sectors such as automotive and construction over the forecast period. The Automotive industry is the major user of Neopentyl Glycol (NPG) and the main driver of NPG market expansion. Neopentyl Glycol (NPG) is pivotal in the automotive sector, enhancing coatings' durability and weather resistance. Its role extends to polyurethane foams for interiors and insulation. In adhesives, NPG improves bonding, ensuring structural integrity during assembly. As a building block for polyester resins, it strengthens various automotive components, while acting as a plasticizer, enhancing flexibility in seals, gaskets, and interior materials. NPG's versatile properties make it integral for high-quality coatings, adhesives, foams, and resins crucial in automotive manufacturing. The global Neopentyl Glycol (NPG) market is anticipated to reach nearly 1080 thousand tonnes by 2032.

Based on region, Asia Pacific region serves as the biggest consumer of Neopentyl Glycol (NPG) driven by escalating requirements in commercial and residential construction, as well as the automotive sector. The surging demand in downstream industries like polyurethane resins, polyester lubricants, and plasticizers has prompted numerous international companies to establish manufacturing facilities in the region, consequently augmenting its overall production capacity. The surge in population and per capita income in emerging economies within Asia Pacific further accelerates the demand for neopentyl glycol in the region for its crucial applications in the automotive and construction sectors. The increasing need for NPG in Asia is anticipated to be driven by a robust demand for paints and coatings, as well as plasticizers.

Based on the end-user industry, the global Neopentyl Glycol (NPG) market is divided into Automotive, Building and Construction, Pharmaceuticals, Electronics, and Others. Among these industries, Automotive industry is the major segment and held approximately 42% of the global Neopentyl Glycol (NPG) market in 2022.

Major players in the Global Neopentyl Glycol (NPG) market are BASF SE, Celanese Corporation, Eastman Chemical Company, LG Chem, Mitsubishi Gas Chemical Company, Inc., OXEA GmbH, Perstorp Orgnr, Polioli S.p.A., Oleon NV, and Shandong Dongchen New Technology Co., Ltd.

Years considered for this report:

Historical Period: 2015- 2022

Base Year: 2022

Estimated Year: 2023

Forecast Period: 2024-2032

This report will be delivered on an online digital platform with one-year subscription and quarterly update.

Objective of the Study:

• To assess the demand-supply scenario of Neopentyl Glycol (NPG) which covers production, demand and supply of Neopentyl Glycol (NPG) market in the globe.

• To analyse and forecast the market size of Neopentyl Glycol (NPG)

• To classify and forecast Global Neopentyl Glycol (NPG) market based on end-use and regional distribution.

• To examine competitive developments such as expansions, mergers & acquisitions, etc., of Neopentyl Glycol (NPG) market in the globe.

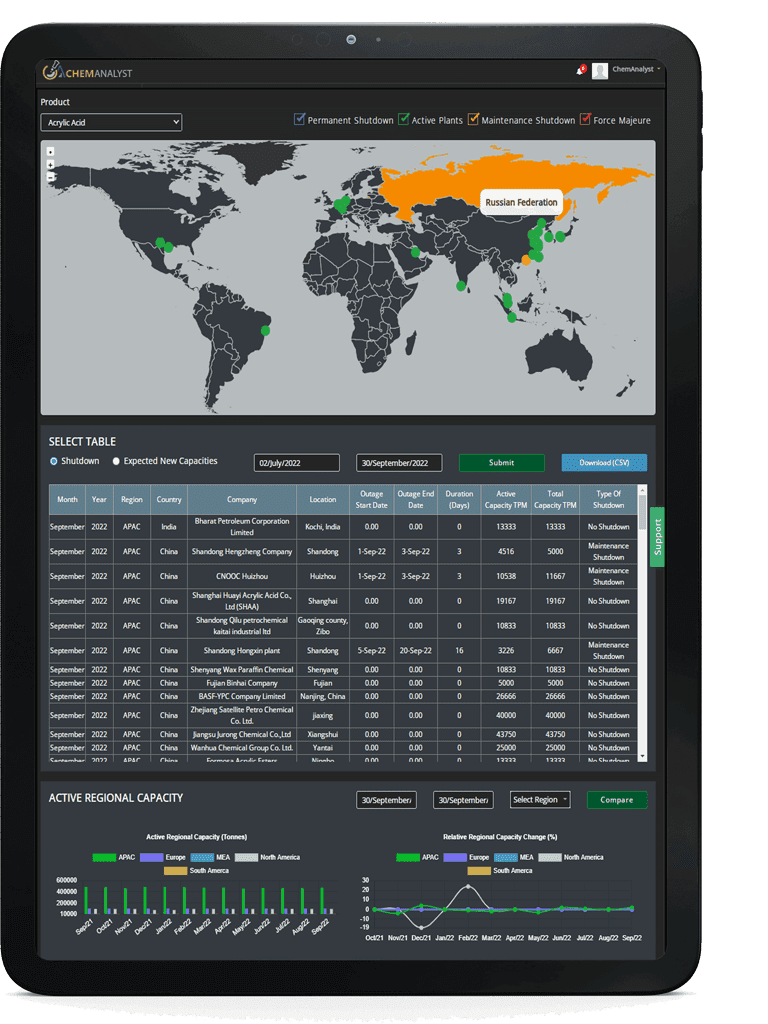

To extract data for Global Neopentyl Glycol (NPG) market, primary research surveys were conducted with Neopentyl Glycol (NPG) manufacturers, suppliers, distributors, wholesalers and Traders. While interviewing, the respondents were also inquired about their competitors. Through this technique, ChemAnalyst was able to include manufacturers that could not be identified due to the limitations of secondary research. Moreover, ChemAnalyst analyzed various segments and projected a positive outlook for Global Neopentyl Glycol (NPG) market over the coming years.

ChemAnalyst calculated Neopentyl Glycol (NPG) demand in the globe by analyzing the historical data and demand forecast which was carried out considering the production of raw material to produce Neopentyl Glycol (NPG). ChemAnalyst sourced these values from industry experts and company representatives and externally validated through analyzing historical sales data of respective manufacturers to arrive at the overall market size. Various secondary sources such as company websites, association reports, annual reports, etc., were also studied by ChemAnalyst.

Key Target Audience:

• Neopentyl Glycol (NPG) manufacturers and other stakeholders

• Organizations, forums and alliances related to Neopentyl Glycol (NPG) distribution

• Government bodies such as regulating authorities and policy makers

• Market research organizations and consulting companies

The study is useful in providing answers to several critical questions that are important for industry stakeholders such as Neopentyl Glycol (NPG) manufacturers, customers and policy makers. The study would also help them to target the growing segments over the coming years (next two to five years), thereby aiding the stakeholders in taking investment decisions and facilitating their expansion.

Report Scope:

In this report, Global Neopentyl Glycol (NPG) market has been segmented into following categories, in addition to the industry trends which have also been detailed below:

|

Attribute

|

Details

|

|

Market size Volume in 2022

|

750 thousand tonnes

|

|

Market size Volume in 2032

|

1080 thousand tonnes

|

|

Growth Rate

|

CAGR of 3.7% from 2023 to 2032

|

|

Base year for estimation

|

2023

|

|

Historic Data

|

2015 – 2022

|

|

Forecast period

|

2024 – 2032

|

|

Quantitative units

|

Demand in thousand tonnes and CAGR from 2023 to 2032

|

|

Report coverage

|

Industry Market Size, Capacity by Company, Capacity by Location, Operating Efficiency, Production by Company, Demand by End- Use, Demand by Region, Demand by Sales Channel, Demand-Supply Gap, Company Share, Manufacturing Process.

|

|

Segments covered

|

By End-Use: (Automotive, Building and Construction, Pharmaceuticals, Electronics, and Others)

By Sales Channel: (Direct Sale and Indirect Sale)

|

|

Regional scope

|

North America, Europe, Asia Pacific, Middle East and Africa, and South America.

|

|

Pricing and purchase options

|

|

Available Customizations:

With the given market data, ChemAnalyst offers customizations according to a company’s specific needs.

In case you do not find what, you are looking for, please get in touch with our custom research team at sales@chemanalyst.com