The global Carbon Fiber market has grown remarkably to reach approximately 157 thousand tonnes in 2024 and is expected to grow at an amazing CAGR of 9.68% during the forecast period until 2035.

Carbon fiber-reinforced strands are known as Carbon Fiber. These substances are all organic polymers, which have lengthy chains of molecules joined by carbon atoms. Around 90% of carbon fiber is manufactured by using Polyacrylonitrile (PAN) precursor. The rest of the 10% is manufactured from rayon or petroleum pitch-based precursor. The composition of raw material varies from company to company, considered as the trade secret. The manufacturing process of carbon is a combination of both chemical and mechanical process. Initial step involves stabilization of the molecule by heating at a temperature range of 390-590 degree Celsius. After stabilizing the material, it is again heated at a very high temperature from 1830-5500 degree Celsius. During this process oxygen is kept out to prevent the fibers from burning at high temperature. For this process some companies utilise either two or more furnaces in order to have better control of heating rates. This whole process is known as carbonization. Later the container is slightly oxidised to provide better chemical and mechanical bonding properties. Surface treatment process must be performed under careful precision, even a slight error could result in defect in the carbon fiber. Finally, the fiber is coated with compatible materials such as epoxy, polyester, nylon, and urethane to protect it during winding & weaving. This complex and tough carbon fiber process has a lot of technological barriers.

Carbon fiber has properties like light weight nature, high strength, exceptional stiffness, thermal stability etc. It is five times stronger than steel. Physical and mechanical properties of Carbon Fiber make it an efficient and reliable material for industries like aerospace, defense, sports equipment, wind energy turbines, automotive industry, and others.

The Aerospace & Defense sector is the market driving factor of Carbon fiber for its excellent properties. In the aerospace industry over 50% of aircraft material is made up of composites (carbon fiber). In this sector, surging demand for lightweight vehicles and drones is expected to swell the Carbon Fiber market in the forecast period. The Aerospace & Defense sector consumed around 50% of total carbon fiber produced in 2024. In the forecast period wind energy is anticipated to play a significant role in the growth of carbon fiber. The global Carbon Fiber market will most likely reach 400 thousand tonnes by 2035.

Based on demand by regions, Europe is dominating the Carbon Fiber market. It is mainly due to the presence of various aircraft and automobile manufacture in the region. Whereas demand in APAC region is going to increase over the period. Countries like China and India are shifting from conventional fossil fuel to more sustainable energy methods, which will most likely increase the demand of Carbon Fiber in the region. On terms of production, USA is taking the lead along with other western countries like UK and Germany. Additionally, Japanese firm such as Toray industries, Mitsubishi, Teijin limited has their own carbon fiber technology which makes them a global player in the market. Although China’s carbon fiber market is anticipated to grow in the forecast period. Chinese companies such as Zhongfu Shenying, Kangde Composites and others has already planned for new carbon fiber capacity in the coming years.

Based on the end-user industry, the global Carbon Fiber market is segregated into Aerospace & Defense, Automotive, Sporting Goods, Wind Energy, Civil Engineering, and Others. Although, the Aerospace & Defense is the leading as a consumer of Carbon Fiber. In 2021, this industry held about 50% of the Carbon Fiber market and is anticipated to show this trend in the forecast period.

Major players in the production of Global Carbon Fiber are Toray Industries, Inc., SGL Group, & others.

Years considered for this report:

Historical Period: 2015- 2023

Base Year: 2024

Estimated Year: 2025

Forecast Period: 2026-2035

This report will be delivered on an online digital platform with one-year subscription and quarterly update.

Objective of the Study:

• To assess the demand-supply scenario of Carbon Fiber which covers production, demand and supply of Carbon Fiber market in the globe.

• To analyses and forecast the market size of Carbon Fiber

• To classify and forecast Global Carbon Fiber market based on end-use and regional distribution.

• To examine competitive developments such as expansions, mergers & acquisitions, etc., of Carbon Fiber market in the globe.

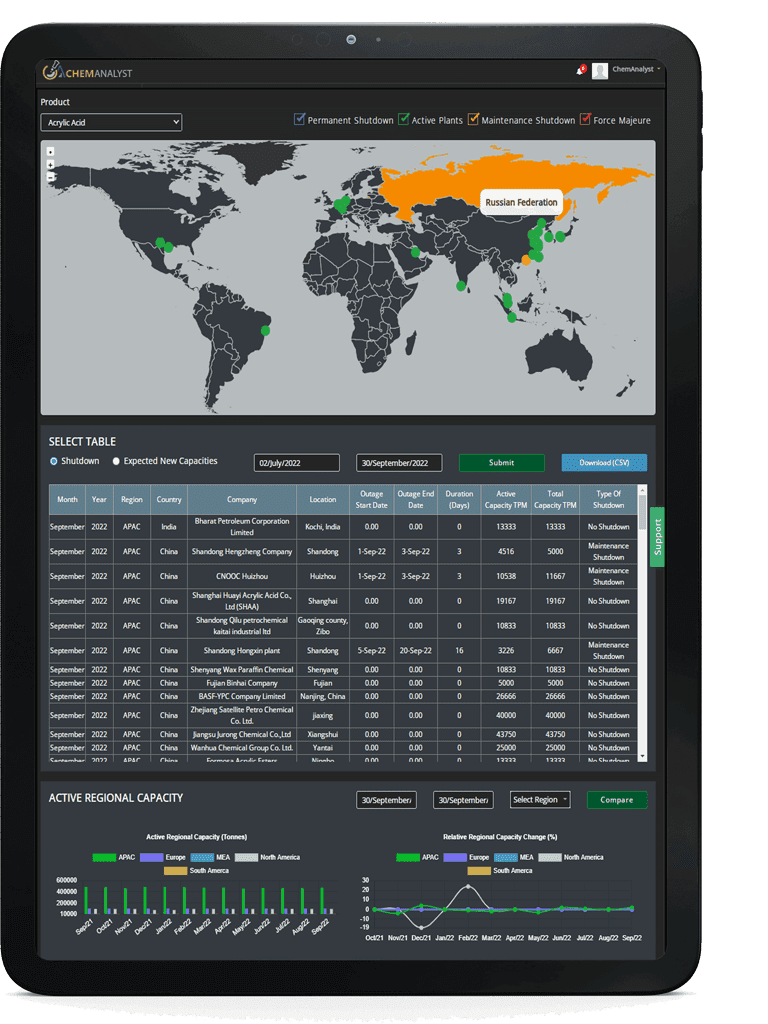

To extract data for Global Carbon Fiber market, primary research surveys were conducted with Carbon Fiber manufacturers, suppliers, distributors, wholesalers and Traders. While interviewing, the respondents were also inquired about their competitors. Through this technique, ChemAnalyst was able to include manufacturers that could not be identified due to the limitations of secondary research. Moreover, ChemAnalyst analyzed various segments and projected a positive outlook for Global Carbon Fiber market over the coming years.

ChemAnalyst calculated Carbon Fiber demand in the globe by analyzing the historical data and demand forecast which was carried out considering the historical extraction and supply and demand of Carbon Fiber across the globe. ChemAnalyst sourced these values from industry experts and company representatives and externally validated through analyzing historical sales data of respective manufacturers to arrive at the overall market size. Various secondary sources such as company websites, association reports, annual reports, etc., were also studied by ChemAnalyst.

Key Target Audience:

• Carbon Fiber manufacturers and other stakeholders

• Organizations, forums and alliances related to Carbon Fiber distribution

• Government bodies such as regulating authorities and policy makers

• Market research organizations and consulting companies

The study is useful in providing answers to several critical questions that are important for industry stakeholders such as Carbon Fiber manufacturers, customers and policy makers. The study would also help them to target the growing segments over the coming years (next two to five years), thereby aiding the stakeholders in taking investment decisions and facilitating their expansion.

In this report, Global Carbon Fiber market has been segmented into following categories, in addition to the industry trends which have also been detailed below:

With the given market data, ChemAnalyst offers customizations according to a company’s specific needs.