Welcome To ChemAnalyst

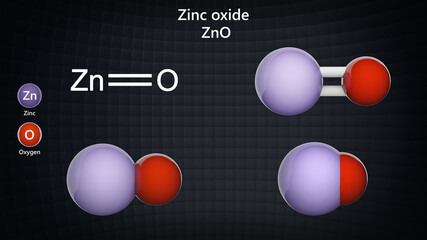

Zinc Oxide (ZnO) is extensively utilized in several products, such as plastics, cosmetics, glass and ceramics, paints, rubbers, batteries, fire retardants, sunscreens, etc. Due to its semiconducting properties, near UV emission, transparent conductivity, and piezoelectricity, Zinc Oxide is used in many electronic applications, like sensors, solar voltaic, transducers, and others. Among many applications of ZnO, the most important relies on the rubber industry as a chemical activator of the vulcanization process as it is considered to be the most significant activator of sulfur vulcanization. Approximately 1.2 million tonnes of ZnO is produced in the world annually, and more than 50% is employed in the worldwide rubber industrial production.

Vulcanization is a large-scale consolidated process in which the rubber is heated with sulfur, accelerator, and activator at 140–160°C. It helps to cross-link rubber chains, forming a three-dimensional network, which further provides mechanical properties, such as elasticity and tensile strength. Basically, Zinc Oxide in the rubber mixtures acts as an activator of Sulphur vulcanization. The addition of ZnO into rubber mixtures helps in improving the abrasion resistance of tires and resistance to dynamic load, including undesirable heating. Some of the key aspects of the curing activation of ZnO are the homogeneous distribution of zinc centers in the polymer matrix, their efficient combination with other curing agents, and their capability to form sulfurating intermediate complexes. Thus, the activation properties of Zinc Oxide are strongly related to its crystal structure and dispersion in the rubber.

Active Zinc Oxide is expected to replace the ordinary Zinc Oxide in the rubber industries in the upcoming period as it exhibits properties that traditional ZnO does not. Chemically processed active ZnO has a large specific surface area and high chemical activity with high dispersibility and adsorption, which can satisfy the demands of special chemicals. The fineness, chemical purity, and particle shape of active ZnO can be adjusted as per need, and it also has a photochemical effect and better UV shielding performance rate as high as 98 percent. In rubber industries, active Zinc Oxide is used in less quantity than ordinary Zinc Oxide for the manufacturing of rubber products and greatly improves the stability, bonding force, wear resistance, and speed of vulcanization, so that the produced products have higher tear and cracking resistance. Activated ZnO can also be used as an anti-softening agent so that the rubber products do not get easily deformed.

We use cookies to deliver the best possible experience on our website. To learn more, visit our Privacy Policy. By continuing to use this site or by closing this box, you consent to our use of cookies. More info.